產品介紹

-

-

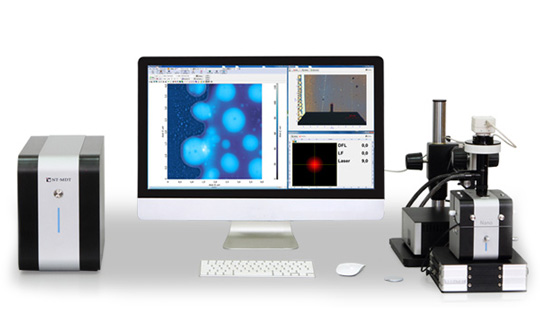

Solver Nano

AFM holds a strong positions in scientific research as is used as a routine analytical tool for physical properties characterization with high spatial resolution down to atomic level. Solver Nano is the best choice for scientists who are need a single instrument that is an affordable, robust, user-friendly and professional tool.

產品說明

產品應用

Scientific research

Solver Nano - AFM for science.

Solver Nano is designed by the NT-MDT team that also created High Performancel Systems like Ntegra, NEXT and Spectra which have been proven in the scientific community through many key publications.

Solver Nano is equipped with a professional 100 micron CL (closed loop XYZ) piezotube scanner with low noise capacitance sensors. Capacitance sensors in comparison with strain gauge and optical sensors have lower noise and higher speed in the feedback signal. The CL scanner is controlled by a professional workstation and software.

These capabilities enable all of the basic (http://www.ntmdt.com/spm-principles) AFM techniques in compact SPM design.

|

Because the SolverNano can be employed in diverse areas of research as AFM tool, several research examples are shown below: :

The following samples were provided by Customers: Nitrocellulose membrane, Celgard, Polystyrene Polybutadiene (PS/PBD), Graphene. |

Configuration and experimental setup: > Solver Nano with AFM head. > CL 100 um piezotube scanner. CL enabled. > Digital controller. > Active vibration isolation. > Results from intermittent contact mode (topography, phase, and amplitude image). |

NSC_05/20° whisker cantilever was used which has a spring constant of 13 N/m and a resonance of 210 kHz.

Scanning parameters: 4.0x4.0 um scanning area with 512x512 points, and scanning rate of 1 Hz.

Sample: Nitrocellulose membrane.

Intermittent Contact mode results from a Nitrocellulose membrane sample.

|

|

|

| Topography | Topography with section line | Cross section profile |

Sample: Microporous Polypropylene (PP) Membrane (Celgard),

Intermittent Contact mode results from a Celgard sample;

A NSC_05/20° whisker cantilever was used which has a force constant of 13 N/m and resonance of 210 kHz.

Scanning parameters: 20 x 20 um and 5x5 um scanning areas with 512x512 points, and scanning rate of 3 Hz

|

|

|

|

| Topography | Phase | Topography with section line | Cross section profile |

Scanning parameters: 2.5x2.5 um scanning area with 512x512 points, and scanning frequency of 30 Hz

|

|

|

|

| Topography | Phase | Topography with section line | Cross section profile |

Sample: Polystyrene Polybutadiene (PS/PBD).

Intermittent Contact mode results from a phase separated blend of Polystyrene Polybutadiene (PS/PBD).

A NSC_05/20° whisker cantilever was used which has a spring constant of 12 N/m and a resonance of 201 kHz.

Scanning parameters: 20 x 20 um and 5x5 um scanning areas with 512x512 points, and scanning rate of 2.5 Hz.

|

|

|

|

| Topography (20x20 um) | Phase | Topography (5x5 um) | Phase |

Sample: Long DNA

It is important to note that all data was collected during an on-site demonstration without any filters applied to adjust the raw data.

Intermittent Contact mode results from long stands of DNA/Mica sample;

A NSG03 cantilever was used which has a spring constant of 2 N/m and a resonance of 80 kHz.

Topography, amplitude and phase image were recorded simultaneously

Scanning parameters: 2.0x2.0um scanning area with 512x512 points, and scanning rate of 0.8 Hz

|

|

|

| Topography | Phase | Amplitude |

|

|

|

|

| Topography with section line | Cross section profile | Topography with section line | Cross section profile |

Sample: Short DNA on Mica

Intermittent Contact mode results from short strands on DNA/Mica sample.

A NSG03 cantilever was used which has a force constant of 2 N/m and resonance of 80 kHz.

Topography and phase images were recorded simultaneously.

Scanning parameters: 1.5x1.5um scanning area with 512x512 points, and scanning frequency of 0.7 Hz.

|

|

| Topography | Phase |

|

|

| Topography with section line | Cross section profile |

Sample: Circular DNA on Mica

Intermittent Contact mode results from circular DNA/Mica sample.

A NSG03 cantilever was used which has a spring constant of 2 N/m and a resonance of 80 kHz.

Topography, amplitude and phase images were recorded simultaneously.

Scanning parameters: 900x900 nm scanning area with 512x512 points, and scanning rate of 0.5 Hz

|

|

|

| Topography | Phase | Amplitude |

|

|

| Topography with section line | Cross section profile |

Sample: Graphene on Si substrate

Topography and surface potential image were recorded simultaneously

A NSG03 cantilever was used which has a spring constant of 2 N/m and a resonance of 90 kHz.

Topography and surface potential were recorded simultaneously

Scanning parameters: 5.0x5.0um scanning area with 512x512 points, and scanning rate of 1.1 Hz.

|

|

|

|

| Topography | Topography with section line | Cross section profile | Surface potential |

Metrology control

SOLVER Nano for metrology applications.

SOLVER Nano AFM can be used for educational / scientific projects as well as for routine measurements. It can also be used as a metrological tool for the determination of linear dimensions of objects in the nanometer range.

|

Technical requirements for metrology appliocations: > Large field scanner – 100x100 um piezotube scanner.> High level XYZ linearity - < 0.1% > Low noise XY sensor – < 0.3 nm in closed loop, < 0.05 nm open loop > Low noise Z sensor – < 0.04 nm in closed loop, < 0.01 nm open loop > Precision capacitance sensors. > Professional software with the common metrological protocols. Sample: Metrology test sample TDG, period 278 nm. Sample: Metrology test sample TGG, period 3 um Signal: Topography. Scanning parameters: 60.0x60.0 um scanning area with 512x512 points, and scanning rate of 1 Hz Sample: Metrology test sample TGZ2, period 3 um, relief height 94 nm. Signal: Topography. Scanning parameters: 60.0x60.0um scanning area with 512x512 points, and scanning frequency of 2 Hz Sample: Metrology test sample TGQ, period 3 um, height 19 nm Signal: Topography. Scanning parameters: 60.0x60.0um scanning area with 512x512 points, and scanning rate of 3 Hz

|

產品規格

| Atomic Force Microscopy Contact AFM Constant Height mode Constant Force mode Contact Error mode Lateral Force Imaging Spreading Resistance Imaging Force Modulation microscopy Piezoresponse Force Microscopy Amplitude modulation AFM Intermittent contact mode Phase Imaging mode Semicontact Error mode Non-Contact mode Electrostatic Force Modes Contact EFM EFM Scanning Capacitance Microscopy Kelvin Probe Force Microscopy MFM DC MFM AC MFM Dissipation Force Microscopy |

AFM Spectroscopies Force-distance curves Adhesion Force imaging Amplitude-distance curves Phase-distance curves Frequency-distance curves Full-resonance Spectroscopy STM techniques Constant Current mode Constant Height mode Barrier Height imaging Density of States imaging I(z) Spectroscopy I(V) Spectroscopy Lithographies AFM Oxidation Lithography STM Lithography AFM Lithography - Scratching AFM Lithography - Dynamic Plowing HD Modes |

General specs:

| Scanner | 100 x 100 x 12 um closed loop scanner, 3x3x3 um open loop scanner. | |

| AFM resolution | 0.01 nm. | |

| Environments | Air and liquid measurements. | |

| Combined video optical microscopes | Build in 100x optical USB microscope. External 500x optical microscope. |

|

| Design | Table-top, affordable, robust and user-friendly | |

| Scanner | ||

| Scanning field | High voltage regime: 100x100x12 um. Low voltage regime: 3x3x3 um. |

|

| Scanner type | Metrological piezotube XYZ scanner with sensors. | |

| Sensors type | XYZ – ultrafast capacitance sensors. | |

| Sensors noise | Low noise XY sensor: < 0.3 nm. Metrological Z sensor: < 0.03 nm. |

|

| Sensors linearity | Metrological XY sensor: < 0.1% Metrological Z sensor: < 0.1 % |

|

| Overall scanner parameters | 100x100x12 um with CL. Resolution: XY -0.3 nm, Z – 0.03 nm. Linearity: XY - < 0.1%, Z - < 0.1%. 3x3x3 um with OL. Resolution: XY -0.05 nm, Z – 0.01 nm. |

|

Sample |

||

| Sample positioning range | 12 mm. | |

| Sample positioning resolution | 1.5 um. | |

| Sample dimension | up to 1,5” X 1,5” X 1/2”, 35x35x12 mm | |

| Sample weight | up to 100 g. | |

| Approach system type | Z – Stepper Motor | |

| Approach system step size | 230 nm. | |

| Approach system speed rate | 10 mm per min | |

| Algorithm Gentle approach | Available (probe guaranteed to stop before it touches the sample) | |

Scanning Heads |

||

| AFM head for Si cantilever | Available. All commercial cantilevers can be used | |

| Type of cantilever detection | Laser/Detector Alignment | |

| Probe holders | Probe holder for air measurements. Probe holder for liquid measurements. | |

| Type of AFM head mounting | Cinematically mount. Mount accuracy 150 nm. (Remove/mount accuracy) | |

| STM AFM head for wire probes | Available. Tungsten wire for AFM measurement. (low cost experiments) Pt|Ir wire for STM measurements. | |

| Type of cantilever detection | Piezo for AFM measurement. | |

| Probe holders | Probe holder for air and liquid measurements. | |

Controllers. Digital professional controller |

||

| Number of images can be acquired during one scanning cycle | Up to 16 | |

| Image size | Up to 8Kx8K scan size | |

| ADC | 500 kHz 16-bit ADC 12 channels (5 channels with software controlling gain amplifiers 1,10,100,1000) Individual filter on each channel |

|

| DSP | Floating point 320MHz DSP | |

| Digital FB | Yes 6 Channels | |

| DACs: | 4 composite DACs (3x16bit) for X,Y,Z, Bias Voltage 2 16-bit DAC for user output |

|

| XYZ scanner control voltage | High-voltage outputs: X, -X, Y, -Y, Z, -Z at -150 V to +150 V Low-voltage mode XY ± 10 V |

|

| XY RMS noise in 1000 Hz bandwidth | 0.3 ppm RMS | |

| Z RMS noise in 1000 Hz bandwidth | 0.3 ppm RMS | |

| XY bandwidth | 4 kHz (LV regime – 10 kHz) | |

| Z bandwidth | 9 kHz | |

| Maximal current of XY amplifiers | 1.5 mA | |

| Maximal current of Z amplifiers | 8 mA | |

| Integrated demodulator for X,Y,Z capacitive capacitance sensors | Yes | |

| Open/Closed-loop mode for X,Y controlх | Yes | |

| Generator frequency setting range | DC – 5 MHz | |

| Deflection registration channel bandwidth | 170 Hz-5 MHz | |

| Lateral Force registration channel bandwidth | 170 Hz -5 MHz | |

| 2 additional registration channel bandwidth | 170 Hz -5 MHz | |

| Bias Voltage | ± 10 V bandwidth 0 – 5 MHz | |

| Modulating signals supply | To the probe (external output); High-voltage X,Y, Z channels (including LV regime); Bias Voltage. |

|

| Number of generators for modulation, user accessible | 2, 0-5 MHz, 0.1 Hz resolution | |

| Stepper motor control outputs | Two 16-bit DACs, 20 V peak-to-peak, max current 130 mA | |

| Additional digital inputs/ outputs | 6 | |

| Additional digital outputs | 1 | |

| I2C bus | Yes | |

| Macro language | ||

| Max. cable length between the controller and SPM base or measuring heads | 2 m | |

| Computer interface | USB 2.0 | |

| Voltage supply | 110/220 V | |

| Power consumption | ≤ 110 W | |

Software for SPM operation and Data processing.

Software written by programmers NT-MDT and specialized management probe microscopes and associated devices (external and build-in) and also signal and image processing obtained with SPM. This software is used to manage all SPM from NT-MDT, but adapted for each model (Next, Ntegra, Solver Nano). In the case of use with Solver Nano, the software interface as much as possible easy and user-friendly.

Operation Interface

> User-defined configurable GUI> Basic and advanced GUI layouts

> Handy hardware configuration wizard

> Quick access for all main parameters

> Quick access to customized scripts

> Automatic single-click setup for all available techniques

> Interactive Help system

Laser alignment

> Handy indication for laser alignmentResonance

> Automatic configuration for standard probes> Automatic resonance tune and phase adjustment

Approach

> Automatic routine for tip-sample engagement> Soft Approach gentle engagement routine

> Handy stepper motor control

> Real time engagement oscilloscope

Scan

> Up to 8 sumultaneous signal channels> Up to 8K points

> Automated single-click scanning mode setup

> Handy scan area selection tool

> Two pass techniques

> Cyclic mode

> Pause tool

> PreScan regime

> OverScan regime

> Angle scanning

> Non-square pixel mode

> Live 3D view

> Quick access to main scanning parameters via Parameters panel

> Quick access to main tuning operations via Quick panel

> Automatic PID setup

> Adaptive scan

> Cross-sections for each and all scans

> Full-screen mode

Curves

> Variety of standard modes> Available arguments: Height, BV, Frequency, SetPoint

> Up to 3 channels measured simultaneously

> Limits for each channel

> Independent setup for resolution and speed for trace and retrace

> Point/Multi Point/Line/Grid measurement modes

Lithography

> Vector/Raster techniques> Constant/Pulse/Gradient regimes

> Force/Voltage/Current modes

> Handy CAD for vector lithography

> Support for main graphical standards for raster lithography

> Scan Area / Litho Mask transparent overlay

Tools

Oscilloscope> Real time signal control

> Average and RMS calculation

> Up to 4 simultaneous signals in the same window

> Multi-window view

> 4 different plot modes

> User markers for measurements

> Data save/export

> Trigger mode to synchronize with other processes

Scheme

> Graphical control for controller schematics

> Access to digital filters

> Access to all Feedbacks parameters

Closed-loop automatic setup and control

Camera for optical view layout

Scripting and Automation

> Nova PowerScirpt language for customized automation

> Support for external dll

> LabView support

> Script Panel for quick access to frequently used scripts

> Automation for all routine setup procedures

Data Processing and Analysis

Data presentation

> Full access to layout setup

> 3D Light/Fast/Wire modes

> Flight over the surface regime

> Square pixel smoothing

> Variety of colored palettes

> Palette editor for custom palettes

> Fast screenshot tool

> Presentation mode quick

Data Management

Import from Graphical format and ASCIIExport to:

> Graphical formats

> ASCII

> Matlab

Tools

> Single/Pair markers for 1D graphs> Point/Line/Angle tools

> Zoom In / Zoom Out

> Pan tool

Data Processing

> Crop> Interpolation

> Local Equalization

> Filter generator

> Fourier filtration

> Flip/Rotate

> Rescale

> Cut Spikes

> Remove scratches/spots/lines

> Tip shape deconvolution

Flattening

> Line by line flattening 0-10 orders

> Surface flattening 0-3 orders

> Batch processing tool

Data Analysis

> Scanner calibration> Correlation analysis

> Grain/Pore analysis

> Fractal analysis

> Data calculator

> Fourier analysis

> Roughness Analysis

- ISO 4287

- GOST 25142

- ASME B46.1

> Bearing Analysis

> Section Analysis